There are also more diverse designs in appearance.

There are also more diverse designs in appearance.

In conclusion, slip-on rubber boots for men offer an incredible combination of convenience, comfort, durability, and style. Perfect for various occasions, they are suitable for both outdoor adventures and urban living. With their waterproof qualities, ease of use, and fashionable designs, it’s no wonder these boots have earned a permanent spot in many men’s wardrobes. Investing in a pair of high-quality slip-on rubber boots is a smart choice for anyone looking to stay stylish while navigating life’s diverse challenges. Whether you're walking through rain-soaked streets or enjoying a hike, slip-on rubber boots ensure that you step out with confidence and comfort.

In conclusion, affordable ankle rain boots are a smart investment for anyone who wants to stay stylish and dry in wet conditions. With various options on the market, you can find a pair that meets your stylistic preferences and practical needs without overspending. So next time the clouds roll in, you'll be prepared to step out in confidence and comfort!

Height: Consider the height of the boots based on your hunting environment and personal preference. Taller boots offer added protection from water, mud, and brush, while shorter boots provide greater flexibility and ease of movement.

What are Composite Toe Neoprene Boots?

Made from durable materials such as rubber or PVC, these boots are designed to withstand wet and muddy conditions without compromising on comfort Made from durable materials such as rubber or PVC, these boots are designed to withstand wet and muddy conditions without compromising on comfort

Made from durable materials such as rubber or PVC, these boots are designed to withstand wet and muddy conditions without compromising on comfort Made from durable materials such as rubber or PVC, these boots are designed to withstand wet and muddy conditions without compromising on comfort women's rain boots cowboy style. The waterproof construction of these boots ensures that your feet stay dry and protected, making them a practical choice for rainy days or outdoor activities.

women's rain boots cowboy style. The waterproof construction of these boots ensures that your feet stay dry and protected, making them a practical choice for rainy days or outdoor activities.

When it comes to hunting, the right equipment can make all the difference, and footwear is no exception. Among the essential gear for any serious hunter, high-quality boots stand out as vital for comfort, performance, and protection. Enter the 2400 gram Thinsulate hunting boots, a game changer in the world of hunting apparel. These boots combine advanced insulation technology with rugged design to ensure that hunters can perform at their best in the field.

From running shoes to cross-trainers, they offer both performance benefits and a trendy appearance From running shoes to cross-trainers, they offer both performance benefits and a trendy appearance

From running shoes to cross-trainers, they offer both performance benefits and a trendy appearance From running shoes to cross-trainers, they offer both performance benefits and a trendy appearance casual types of shoes. Brands like Nike, Puma, and Under Armour lead this category with their innovative designs and advanced technology.

casual types of shoes. Brands like Nike, Puma, and Under Armour lead this category with their innovative designs and advanced technology.

The insulation is often designed to retain heat without adding bulk, striking a perfect balance between warmth and maneuverability The insulation is often designed to retain heat without adding bulk, striking a perfect balance between warmth and maneuverability

The insulation is often designed to retain heat without adding bulk, striking a perfect balance between warmth and maneuverability The insulation is often designed to retain heat without adding bulk, striking a perfect balance between warmth and maneuverability short insulated rubber boots.

short insulated rubber boots.Comfort and Fit

Mortar bonding additives are widely used in both residential and commercial construction. They are particularly valuable in renovation projects, where bonding to existing materials can be challenging. In such cases, additives can significantly improve the bond strength, allowing new materials to adhere securely to older surfaces.

In the food industry, HEC serves as a thickener, stabilizer, and emulsifier. Its ability to form stable emulsions while maintaining clarity makes it an attractive choice for products like sauces, dressings, and dairy items. Moreover, its solubility in cold water is advantageous for instant food products, as it can be easily incorporated without requiring heat to dissolve. This not only simplifies processing but also helps in retaining the nutritional quality of food items.

What Are Cement Adhesive Additives?

In addition to technology consulting, HPMC Solutions LLC prides itself on its project management capabilities. Every successful project begins with meticulous planning and execution, and the firm excels in both these aspects. By utilizing proven methodologies and frameworks, HPMC Solutions LLC ensures that projects are delivered on time, within scope, and aligned with budgetary constraints. Their team of project managers works closely with clients to establish clear objectives, monitor progress, and address any issues that may arise during the project lifecycle.

Redispersible polymer powder (RPP) is a versatile material widely used in construction, coatings, adhesives, and various other applications. The unique properties of RPP, which allows it to be redispersed in water after drying, offer numerous advantages to a variety of industries. This article will explore the key applications of redispersible polymer powder, highlighting its importance and benefits.

3. Market Demand The demand for construction materials, which RDPs are integral to, directly affects their pricing. In regions experiencing construction booms, demand for tile adhesives and other applications incorporating RDPs can surge, leading to higher prices. Conversely, in times of economic downturn or reduced construction activity, prices may stabilize or decline due to decreased demand.

4. Food Industry While its use in food-grade applications is less common, HEC can act as a thickener and stabilizer in certain food products, contributing to texture and mouthfeel.

Conclusion

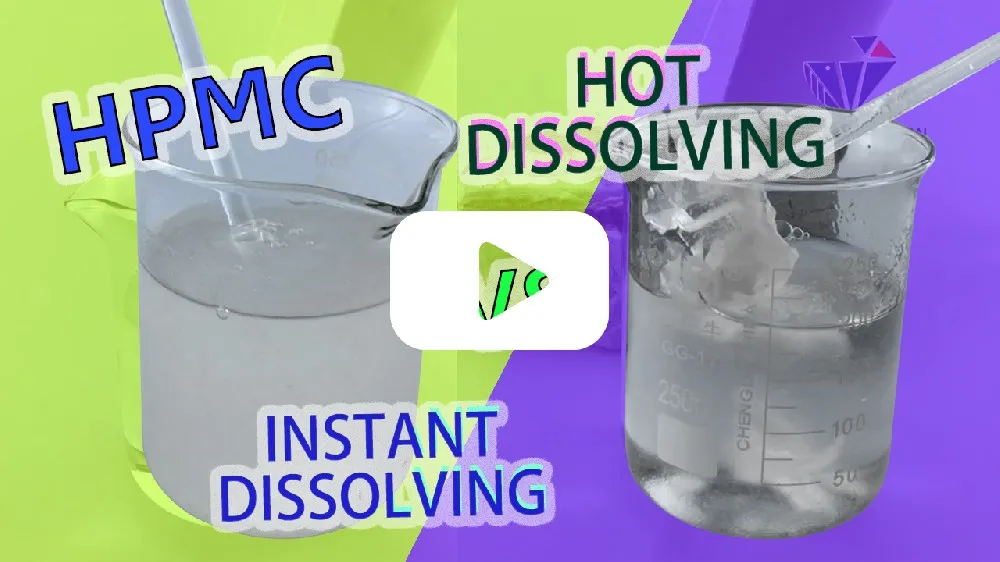

What is HPMC?

Chemical Structure and Properties

5. Paints and Coatings

In construction, HPMC is utilized as an additive in cement and gypsum-based products. The viscosity of HPMC affects the workability and consistency of the mortar or plaster. Engineers and builders often rely on specific grades to achieve the desired level of adhesion, water retention, and workability in construction materials, ensuring that the end products meet safety and durability standards.

2. Cosmetics The cosmetic sector heavily relies on hydroxyethyl cellulose for its thickening and emulsifying properties. It is commonly found in products such as sunscreens, hair conditioners, and facial masks. HEC helps improve the spreadability of these products while also providing a pleasant feel upon application.

This modification enhances the solubility of cellulose in water, allowing HEC to dissolve and form viscous solutions. The presence of hydroxyethyl groups increases the hydrophilicity of the cellulose molecule, which is critical for its functionality in various applications. The degree of substitution, which indicates the average number of hydroxyethyl groups attached per anhydroglucose unit, affects the properties of HEC such as its solubility, viscosity, and gel-forming ability. Generally, higher degrees of substitution result in better soluble derivatives and higher viscosity of the solutions.

Redispersible polymers are a valuable innovation in material science, bridging the gap between traditional materials and modern application demands. Their ability to enhance adhesion, flexibility, and workability makes them a preferred choice for construction materials, coatings, and adhesives. As the construction industry continues to evolve with a focus on sustainability and efficiency, the role of redispersible polymers is likely to expand, leading to more durable, high-performance materials that meet the rigorous demands of contemporary projects.

Types of Redispersible Polymer Powders

Once the emulsion is produced, the next phase involves the spray drying process. This is a critical step in transforming the liquid emulsion into a dry powder form. The emulsion is pumped through a nozzle into a hot air chamber, where it is atomized into fine droplets. As these droplets enter the hot air, they rapidly lose moisture and solidify into polymer particles. The temperature and airflow in the spray drying chamber are meticulously controlled to ensure that the particles attain the desired size and morphology. The resulting redispersible polymer powder is fine and free-flowing, which is essential for easy handling and application.

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose derivative that has garnered significant attention across various industries, particularly in pharmaceuticals, food processing, and construction materials. As a semi-synthetic polymer, HPMC combines properties of natural cellulose with enhanced functionalities, making it an essential component in many formulations and applications.

Hydroxypropyl Methyl Cellulose (HPMC) A Versatile Polymer in Chinese Industry

HPMC solutions exhibit non-Newtonian behavior, meaning their viscosity changes with the applied shear rate. This pseudoplastic behavior is beneficial in various applications, as it provides ease of application (low viscosity during application) while maintaining stability (high viscosity during rest). In the construction industry, for instance, this property is crucial for ensuring proper adhesion and workability of cement mixtures.

3. Construction The construction industry utilizes HPMC as an additive in cement and mortar mixes. Here, viscosity plays a crucial role in workability, ensuring that the final product maintains the desired consistency for application.

Applications of HPMC

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer widely used in various industries, including pharmaceuticals, food, cosmetics, and construction. Its unique properties, including its ability to modify solubility, make it a valuable ingredient in many formulations. In this article, we will explore HPMC solubility, its factors, significance, and relevance in real-world applications.

What is Redispersible Polymer Powder?

Methyl hydroxyethyl cellulose manufacturers play a pivotal role in supplying this essential ingredient across various industries. Its unique properties make it indispensable in enhancing the performance and quality of a wide range of products. With ongoing advancements in manufacturing processes and a growing demand for sustainable solutions, MHEC is poised for continued growth and innovation in the years to come. As industries evolve, MHEC manufacturers will remain at the forefront, driving improvements and contributing to the advancement of diverse applications.

The synthesis of hydroxyethyl cellulose generally involves several key steps

Applications of HPMC in Tile Adhesives

Advantages of HPMC

In conclusion, HPMC solutions are integral to numerous applications, showcasing the adaptability and benefits of this polymer. From enhancing drug formulations to improving food quality, contributing to construction materials, and creating effective cosmetic products, HPMC is a testament to the power of innovation derived from natural resources. As industries continue to seek sustainable and efficient solutions, HPMC is poised to play an increasingly prominent role in meeting those demands, driving advancements in technology and product development. Its unique properties make it not just a functional ingredient, but a vital component in shaping the future of various sectors.

Benefits of Using Cement Adhesive Additives

Hydroxypropyl methylcellulose (HPMC) is a cellulose derivative that has gained significant attention in various fields, particularly in pharmaceuticals and food industries. Its versatility as a thickener, stabilizer, emulsifier, and film-forming agent has made it a staple in many products. The Safety Data Sheet (SDS) for HPMC is an essential document that provides crucial information regarding the substance's handling, hazards, and safety precautions. In this article, we will delve into the key aspects of HPMC and its associated SDS, emphasizing safe practices and its applications.

1. Quality and Purity The quality of HPMC is paramount, particularly in applications related to food and pharmaceuticals. Ensure you source HPMC from reputable manufacturers who can provide certification regarding the product’s purity and absence of harmful contaminants. Testing results and compliance with international standards, such as FDA or EU regulations, are crucial indicators of quality.

RDP is a polymer that can be redispersed in water, meaning it can be reactivated and mixed back into a liquid form after drying. Typically, RDP is derived from various vinyl acetate or ethylene copolymers. The powder form is convenient for storage and transportation, while its ability to easily integrate into different systems makes it an invaluable resource in construction.

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used cellulose derivative that has found applications in various industries, particularly in construction and pharmaceuticals. HPMC is a crucial ingredient in many products, owing to its unique properties such as water retention, emulsification, and film-forming capabilities. As the demand for HPMC has surged in recent years, manufacturers have stepped up to meet this growing need. This article explores the role of HPMC manufacturers and their impact on different sectors.

Understanding Hypromellose (HPMC) A Multifunctional Polymer

HPMC is a key ingredient in many personal care and cosmetic products, including shampoos, conditioners, lotions, and creams. Its thickening and stabilizing properties enhance the consistency and performance of these products, ensuring a smooth application and improved sensory experience for users. In skin care formulations, HPMC provides a protective moisture barrier, aiding in the retention of hydration.

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble cellulose ether that has garnered significant attention in various industries due to its versatile properties and applications. Derived from natural cellulose, HEC is modified through the introduction of hydroxyethyl groups, which enhance its solubility in water and contribute to its unique characteristics. This article delves into the properties, applications, and benefits of hydroxyethyl cellulose, illustrating its importance in contemporary formulations.

Reaction control: Select appropriate paint thinner and control parameters such as reaction temperature, time, stirring speed, etc.

Quality Standards and Production Practices

HPMC is derived from cellulose, a natural polymer found in plant cell walls. The chemical structure of HPMC is modified to introduce hydroxypropyl and methyl groups into the cellulose backbone. This modification enhances its solubility in water and imparts specific functional properties, making HPMC an ideal choice for various formulations.

One of the most significant features of dispersible polymer powders is their ability to enhance the performance of various formulations. They improve properties such as adhesion, flexibility, durability, and water resistance. Additionally, these powders can modify the viscosity and stability of the end product, making them essential for achieving desired performance characteristics.

Conclusion

The Importance of Quality Control

Hydroxypropyl methylcellulose (HPMC) is a widely used cellulose ether in various industries due to its unique properties, such as its thickening, film-forming, and emulsifying abilities. Manufacturers of HPMC play a crucial role in producing this versatile compound, catering to a diverse range of applications from food production to pharmaceuticals, construction, and cosmetics.